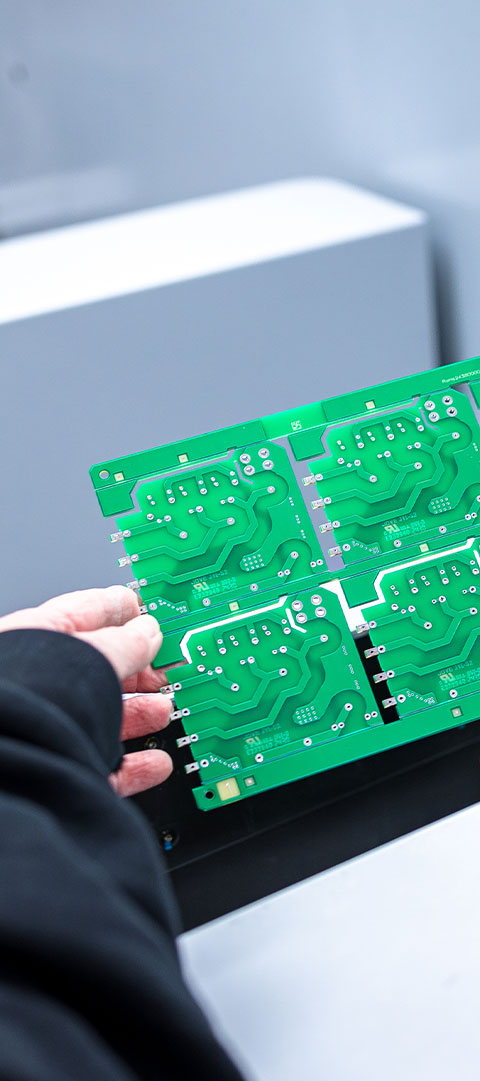

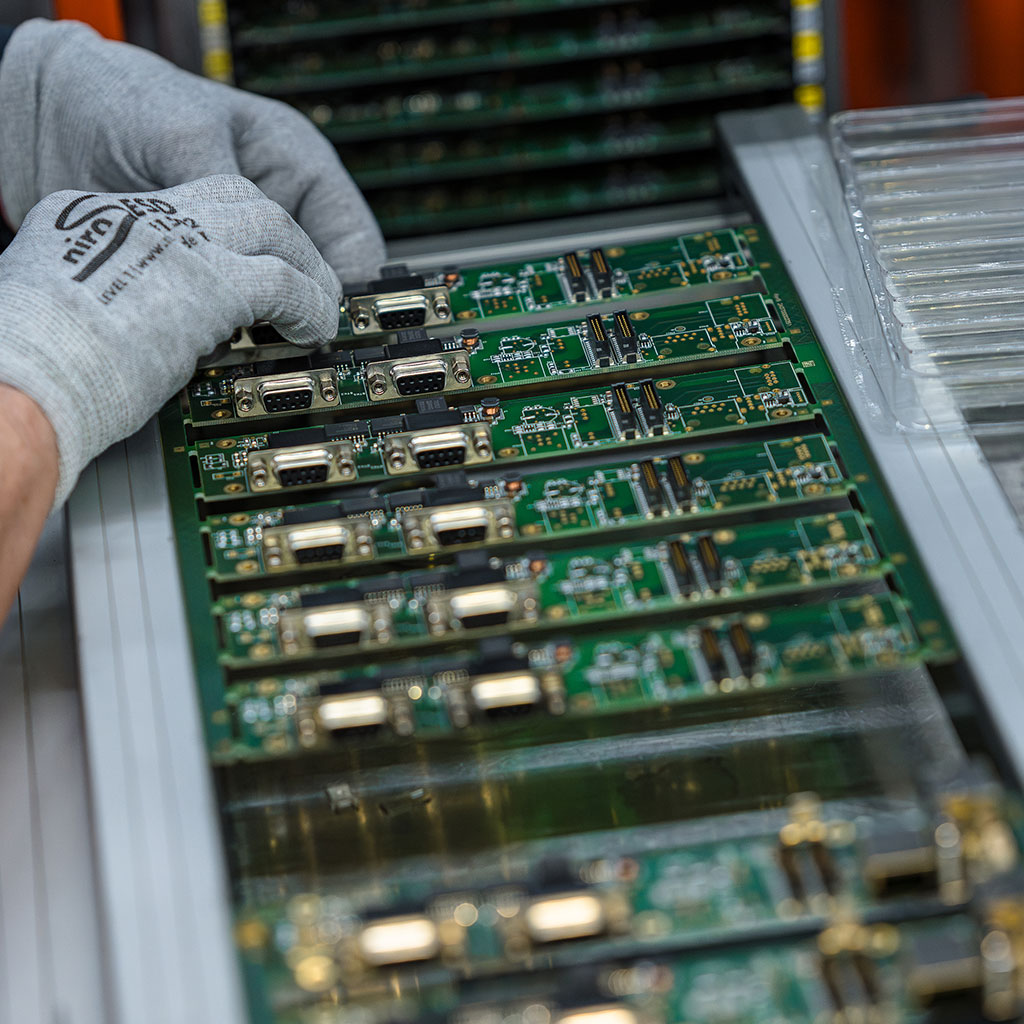

FROM SMT TO Box Build -

excellent electronics manufacturing from Limtronik

Electronics manufacturing is a complex process that requires precision, expertise, and innovative technologies to produce high-quality electronic products. From surface mount technology (SMT) to complete box builds, the final mounting of electronic assemblies in housings, Limtronik covers the full spectrum of electronics production. Our aim is to use advanced manufacturing techniques and strict quality controls to deliver products that will not only meet the current requirements but will also withstand future challenges.

![[Translate to English:] Kontaktieren Sie uns [Translate to English:] Kontaktieren Sie uns](/fileadmin/limtronik_de/abbinder/kontakt-elektronikfertigung.jpg)