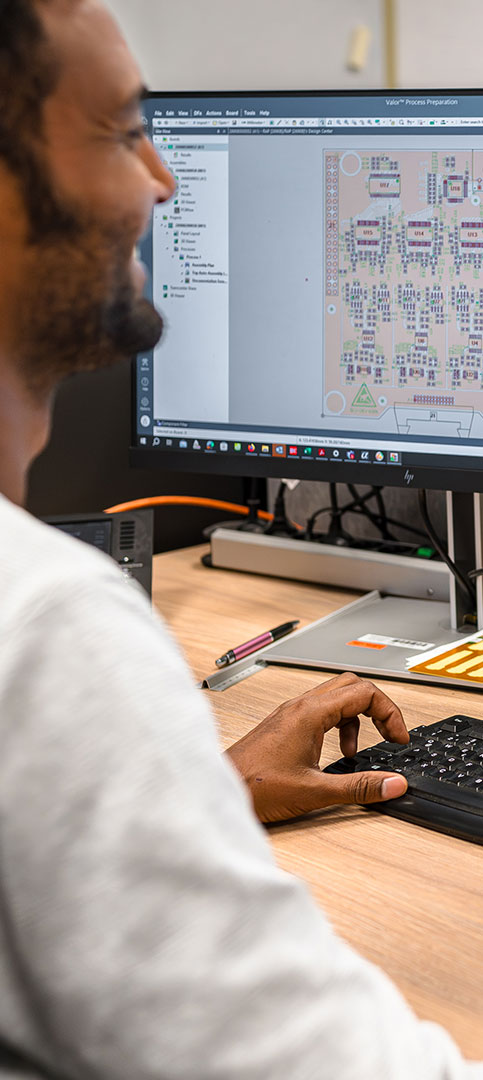

2 questions for Andreas Faber, Team Lead Technology

What sets Limtronik apart from other providers in the field of “Design for X”?

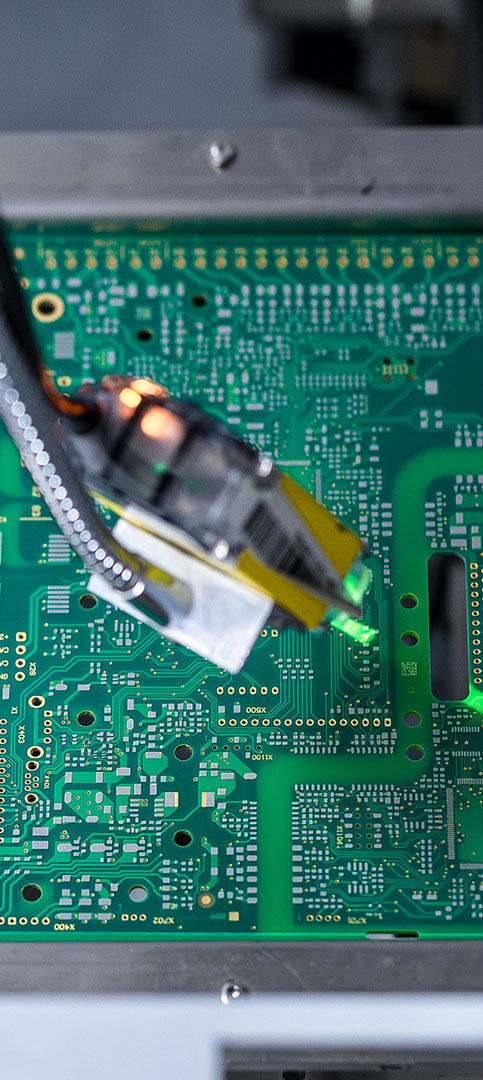

Our approach at Limtronik goes far beyond traditional product development. By integrating “Design for X” strategies into every step of the development process, we not only ensure the technical feasibility and marketability of your products, but also pay attention to cost optimization, quality assurance, and the fulfillment of specific customer requirements. In this context, particular emphasis is placed on material testing and availability, as well as on the efficient manufacturing of components. We offer our customers added value that goes far beyond the norm, including a detailed written report highlighting the measures taken and potential areas of optimization.